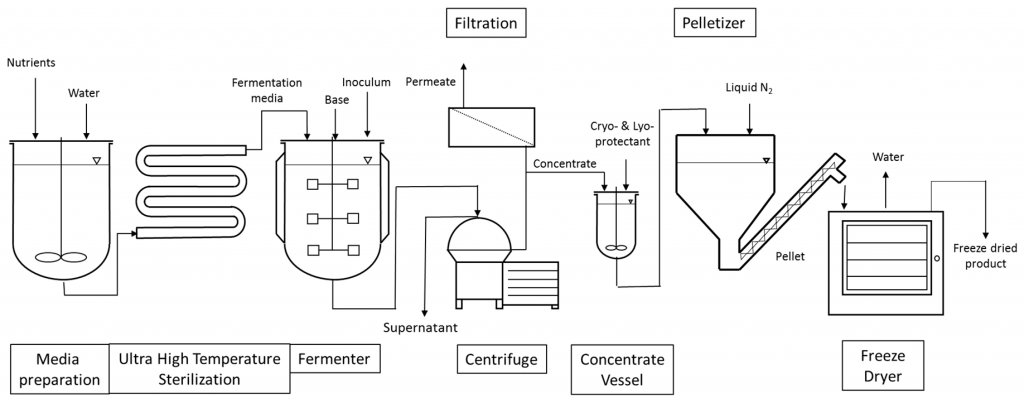

When using a laboratory freeze dryer, simple mistakes are made. The solutions for suck kind of basic mistakes that are made in lyophilization in the laboratory are provided here. Considering these solutions that are suggested can improve your samples quality and extends freeze dryer life span.

Incompatible Samples:

Usually a specimen is kept on freeze dryer without any concern as to the sample’s compatibility with the freeze dryer specifications. When lyophilizing procedure is taking place, it is crucial in determining the sample’s components and needs for the lyophilization. The incompatibility leads to diminished nature of the freeze-dried specimen and all the more critically might cause harm to vacuum pump or freeze dryer.

Collector Temperature:

It isn’t basic in realizing exact the solidification point of a specimen, evaluating the general freezing point or eutectic temperature of your specimen is critical. Normally, the freeze dryer collector temperature of the stop dryer is prescribed to be starting from 15° C to 20° C underneath the point of solidification of specimen. This distinction is important for keeping the specimen solidified amid essential drying and to successfully trap the lyophilized vapours even before they achieve the vacuum siphon.

The collectors have settled temperatures at – 50° C, – 84° C and – 105° Celsius. For the samples of fluid, a collector temperature of – 50° C is sufficient. At the point when solvents are available in tests, the point of solidification is stifled. For tests containing acetonitrile, a collector temperature of – 84° C is prescribed and for tests with up to ten percent methanol, a collector of – 105° C is suggested. Utilizing freeze dryer with a collector doesn’t cause any damage that is colder than the base necessity.

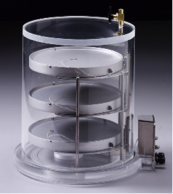

Size of Collector:

It is essential to guarantee the collector size is enormous to oblige the volume of the whole load of sample. Ceasing a run and then defrosting the gatherer isn’t a perfect choice. It is less demanding to ensure that your whole run can be suited before beginning the run. Using a collector that is larger than the base size necessity doesn’t cause any damage.

Compatibility of Component

A few specimens may contain mixtures that require extraordinary parts in the framework of freeze dry. Acids, solvents and particulates are normal intensifies that can be obliged with alterations.

Acids:

The PolyTetraFluroEthylene coatings secure treated steel coils and collectors.

Solvents:

When a solvent harms acrylic lids, at that point, glass covers are utilized.

Particulates:

Inline HEPA channels, kept between the authority and the vacuum siphon, shield vacuum siphons from harm from the particulates.

Vacuum Pump Damage

Keeping up profound vacuum levels is the most well-known issue in freeze drying of a laboratory. The main source of deficient vacuum levels in a freeze dry framework is due to harmed vacuum pump. If vapours are not gathered on the loops in the gatherer, they will enter the pump of vacuum. Oil vacuum siphons are the most helpless to harm from these vapours. The vapours will consolidate in the siphon and blend with the oil. When blended in the oil, water can make harm the vacuum pump while acids and solvents can cause more harm. Blend revolving diaphragm or vane and parchment siphons are impervious to unsafe vapours. Yet at the same time can be harmed from presentation. Harm to any vacuum pump is kept away by obstructing vapours from entering the pump. Guaranteeing the similarity of the specimens to freeze dryer is the most essential deterrent advance to vapours entering the siphon. Here are some proposals.

Start-up Sequence:

For keeping the vapours from entering the siphon, ensure the coils of collector have cooled to at any rate of – 40° C before the vacuum siphon is begun. If the coils of collector are not at sufficient temperatures, they won’t trap dampness from the air and any unstable vapours amid pull down of framework. Having a cleanse valve that permits the vacuum siphon oil to warm up before framework pull down will keep vapours from consolidating in the hot oil.

Shut down:

Most of vacuum siphons have a gas counterbalance that can be utilized to cleanse regulations from oil of pump. After the run of freeze dry, a siphon ought to be permitted to work with the gas weight open for twenty to thirty minutes. This gives any vapours that consolidated in siphon, an opening in which to leave the siphon. Running the siphon warms the oil with the goal that the contaminants are refined out of the oil.

Maintenance:

Constant changes in oil will confine the harm to the siphon, if vapours enter the siphon. Amid these changes, flushing liquid can be utilized to wash away any defiles inside the vacuum siphon. It is vital that oil levels are kept up and pumps are never permitted to keep running above or beneath the suggested levels of oil.

Maintenance of Freeze Dryer

The freeze dryers are research center workhorses that are utilized for a considerable time length with little thoughtfulness regarding their support needs until one day they never again work. With almost no exertion, the life expectancy of a stop dryer can be expanded.

Emptying the Collector:

It is simple to take the finished lyophilized specimen and disregard defrosting and emptying the ice present in collector, towards the end of a run. Restricting the water introduction or more terrible, solvents and acids to the stop dryer will stretch its life expectancy. Collectors of freeze dryer ought to be defrosted, depleted and cleaned down following each utilization. Killing coils of collector after any corrosive introduction is basic. If the gatherer isn’t depleted, and the fluid isn’t seen before the following start up, the fluid of collector will be maneuverer into the vacuum siphon. Some stop dryers include channel line locators to keep this support bad dream from happening.

Checking Lids for Crazing:

With stretched out presentation to a few solvents, as acetonitrile, after some time, acrylic can get craze. Top crazing can bargain vacuum levels and whenever permitted to proceed, may make the top implode when presented to profound vacuums. Supplanting top with obvious crazing or utilizing a glass top while lyophilizing contrary solvents will wipe out downtime of stop dryer. These basic oversights are dispensed with in to solidify dryers as their plans offer numerous highlights that make solidify drying and maintenance of freeze dryer less demanding.

Highlights, for example, remote warning of working and upkeep cautions, one-catch information logging, auto start-up and available diagnostics. These are only a couple of the highlights accessible for labs that need a lyophilizer that will give top notch results, with little issues and keep going for a considerable length of time.

Visit FirstSource Laboratory Solutions LLP for any kind of evaporation and drying instruments.

FirstSource Laboratory Solutions Official Blog First Indian Scientific Online Shop

FirstSource Laboratory Solutions Official Blog First Indian Scientific Online Shop