The word Autoclave is derived from the combination of a Greek word meaning self and Latin Clavis meaning key called as a self-locking system. An autoclave is a high heated container, used for chemical reactions and multiple processes by using high temperatures and pressures.

Autoclaves are available in different types and used for varied purposes. Like, in chemical industries they are used to cure coatings and to harden rubber. Autoclaves are also used for hydrothermal synthesis by growing crystals under high pressures or temperatures. The main feature of autoclaves is its operational use under high temperatures and pressures. For example, in industries like car manufacturing or airline industries, they are mainly used for curing composite materials under a heated nitrogen atmosphere.

As we read further, we will learn how autoclaves use a steamed atmosphere within the pressure vessels which are designed to be used for sterilization. Autoclaves are available in different types and are designed for various purposes. Before investing in purchasing an autoclave, it’s important to know the right type of autoclave that you’re looking for as per the usage or purpose you have.

Operational Usage of Autoclaves as Sterilizers

Steam sterilizers and autoclaves used as sterilizers are completely alike. Autoclaves that are used for steam sterilization come in different types. They broadly fall into three categories used as steam sterilizers but designed for different operational purposes.

They are found in hospitals by doctors and dentists. They are in the form of small tabletop instrument sterilizers which are commonly used. These sterilizers are designed to provide quick and reliable sterilization of small batches of surgical instruments generally with one or two fixed cycles.

The groups who make use of this type of autoclaves are large hospitals and pharmaceutical sterilizers are designed to process them in huge numbers on an industrial scale.

The third group is laboratories or research grade autoclaves. These autoclaves are specifically designed to sterilize a vast range of sterilizing loads with its ability to set different temperatures and time well suited for individual loads.

Autoclave Types and Its Purpose

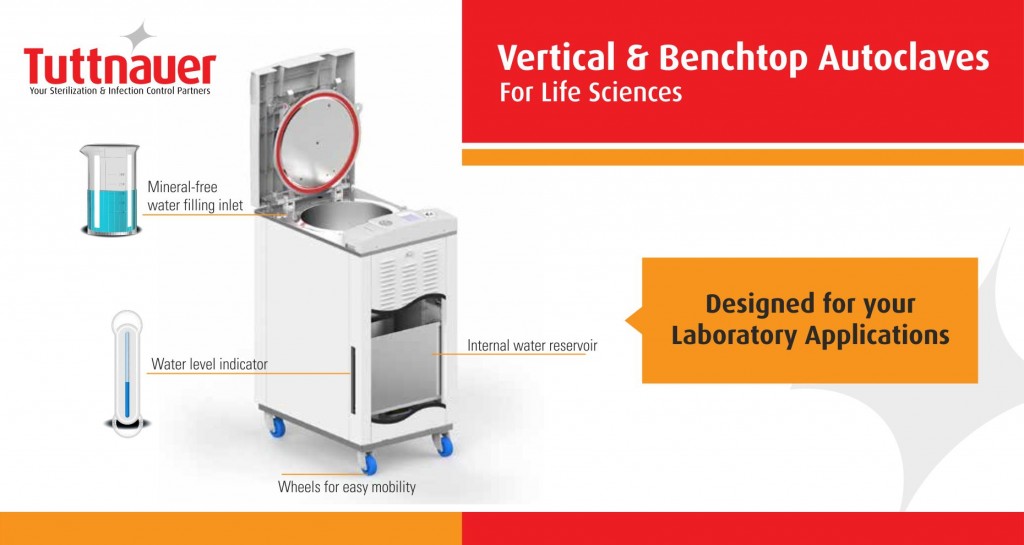

Manufactures produce various types of laboratory autoclaves which are designed for different purposes. Hence, it’s imperative to understand your laboratory requirements in terms of frequency and load variation of sterilizing applications. Requirements can also range in terms of available lab space, a benchtop or larger capacity free-standing is convenient or a front or top loading autoclave is more suitable. Autoclave manufacturers engineer their products to offer customized solutions to meet the client’s needs as per the specifications provided in terms of laboratory space and sterilizing needs. The final decision on purchase will mostly be a compromise in terms of installation space, suitable for applications and available finances.

To buy different types of Autoclaves visit https://www.firstsourcels.com/sterilizing/autoclave

The three main types of autoclaves are Benchtop, Top loading, Front loading, Pass-through. These are available in different door types, heating methods and chamber configurations, each offering distinguished benefits.

Benchtop Autoclave for Small Laboratories

Benchtop autoclaves is an appropriate choice for small laboratories having limited space, hence the sterilization items used are relatively small and throughput being infrequent. This type of autoclave specifically designed to be placed on a lab bench. This shape of equipment is practically an independent machine, with a standalone design, that can be easily connected to an appropriate power supply. It’s easy to install and is relatively one of the lowest priced models.

Benchtop autoclaves is an appropriate choice for small laboratories having limited space, hence the sterilization items used are relatively small and throughput being infrequent. This type of autoclave specifically designed to be placed on a lab bench. This shape of equipment is practically an independent machine, with a standalone design, that can be easily connected to an appropriate power supply. It’s easy to install and is relatively one of the lowest priced models.

Top Load Autoclaves

Use of Top loading autoclaves is basically a practical choice for laboratories which are smaller, but yet the demand for high-quality performance of steam sterilization is expected. Top loading autoclave models tend to increase in height due to high capacity. The main advantage for smaller laboratories is the ‘footprint ‘of the autoclave which ideally doesn’t need much width and depth outside the chamber space.

Front Load Autoclaves

This model of laboratory autoclave comes in circular or rectangular sterilizing chambers. This type of autoclave has an advantage over top loading autoclaves as they are convenient to load. However, this autoclave requires a huge space. The sterilizing capacity of the rectangular chamber of a front-loading format is higher than a top loading cylindrical model.

For Vertical & Benchtop Lab Autoclave please visit https://www.firstsourcels.com/tuttnauer

Pass-Through Autoclaves – Double Door Sterilizer

A lab is used to carry out various processes and procedures. To conduct such procedures a sterile environment is a must. Hence a clear and secure exit path for the waste to be discarded. The pass-through autoclaves are designed to provide a sterilized exit path in and out of closed laboratories. Pass through autoclaves are also called as double doors.

These autoclaves are also used as a containment application, wherein de-contamination of material before its release from the containment suit which would ideally be a laboratory handling high-risk hazardous materials.

This type of autoclaves is heavily modified in their design, in which two units are placed one behind the other with a single chamber open on both ends to allow for doors at either end. When buying a pass-through autoclave it’s advisable to involve the manufacturer at the initial stage of planning depending on the sites you choose. Each site may have different requirements like hinged doors to swing left or right, water and drain services, the location of the electrical. Thus a manufactures needs to be kept in a loop from the initial start itself. A pass-through autoclave usually tailor-made to meet the customer specific application.

Sterilizing Chamber

Sterilizing chambers are usually manufactured in stainless steel which comes in two shapes rectangular or round. The round chambers are also called cylindrical chambers which are most common. These round chambers are found in two types- top loading and front loading autoclaves. A cylindrical chamber consists of thinner walls which makes up for less heated metals and quickens up the heating process. It weighs less and is very economical to produce and this reflects in its overall cost. Steam is a sterilizing medium used in an autoclave and it is important that the items be sterilized come in full contact with the steam in the autoclave with all air being removed. Hence a big advantage of the round profile of a chamber and the square profile of the autoclave is that there will be space around the sides of the load for circulation of steam. Due to better steam circulation, a cylindrical chambered autoclave will not call for assistance for air removals like a vacuum system or pulsed steaming.

Closure Systems for Autoclaves

One needs to be cautious when buying an autoclave model. Operating an autoclave with pressure is very dangerous and extreme caution needs to be maintained. The model needs to have safety interlocks which can prevent a door from opening during elevated pressures and high temperatures. The model should be designed in a way that the door is prevented from opening until the load is at a safe temperature. The manner in which the doors of an autoclave open and close differs based on the models produced by manufacturers, as each autoclave is manufactured with a range of different closure systems.

The types of Precautionary doors are:

- Hinged or swing doors-

- The manual door having hand bolts

These doors are less complex and hence the servicing is relatively inexpensive. These doors are not very easy when opening and closing the doors as compared to single action closure. Adequate space is required in front of the door and to the hinged side of the autoclave to let the door swing while opening.

Manual Doors Having Single Action Closure

These doors are quick and conveniently operated than hand bolt doors. They are not as complex than powered door closures. It requires less servicing and is inexpensive. These doors cannot be opened and closed with ease than push-button operation. Ample space is required at the front and side of the autoclave to allow the door to swing when opened.

Horizontal or Vertical Powered Sliding Doors

If a higher capacity chamber is handling heavier items, in a laboratory having insufficient space for a hinged door opening, it’s always advisable to have a power door autoclave. The advantage of having this would be that the chamber door lowers within the body of the machine. These machines are user-friendly with simple fast push-button functionality with minimal physical effort. But these machines are more complex and expensive due to the varied controls and mechanisms required to move the door in the right position and sealing it. An autoclave with a fixed sealed design is a right choice as the door physically moves onto the seal, causing minimal wear and tear.

Regular servicing of these systems is mandatory.

Steam Generating Methods

There are mainly three procedures for generating steam – one having direct steam and two electrical steams.

Electrical Heating Method

This method uses heating elements within the chamber. It is a simple form of heating method wherein water is poured into a reservoir to a certain level. This method requires less servicing, and at the same time is affordable and not very complex to use. The only disadvantage of this method is due to the hot water at the bottom of the reservoir built in the autoclave which takes a longer time to cool down with the load. Few autoclaves can be drained to improve cooling duration, for which an automatic filling system is required to refill before the next cycle begins.

Built-In Electrical Heated Steam Generator

In this method, an individual steam generator is fitted beneath the chamber attached to the main autoclave vessel. As with the in chamber system, the steam generated is controlled by the autoclave temperature controller. These electrical generators are expensive but offer a cleaner workspace and dry loads at the end of the cycle. It has the ability to speed up the cycle times if required. Additionally, it achieves faster cooling than in chamber electrical models.

Built-In Electrical Heated High Pressure ‘On Demand’ Type Generator

This model is best suited for laboratories where autoclave work is continuously flowing. This type of electrical generator maintains a supply of high steam pressure available on demand and is comparable in performance with an external steam supply or an individual steam generator.

Due to the frequent supply of steam from the heaters operating all day makes the process more complex and calls for regular servicing. It is relatively expensive as the autoclaves run at a continuous flow. The main advantage is that it offers a faster startup and cooling service as compared to ‘in chamber’ electrical heated models.

Steam Heated from An External Source

An autoclave needs good quality dry steam to be operational and while an existing connection to an available steam source should be perfect; however some in-house supplies can be non-reliable. To meet this requirement manufacturers supply autoclaves with a ‘back-up’ electrical heating when a steam supply is not readily available.

The main use of getting steam from an in-house steam room includes faster heating of chambers due to the available high steam temperatures inside the autoclave, as compared to electrically heated models.

Important Rules to Be Taken Into Account to Produce Better Sterilization

For bottled liquids – Thermal cooling lock, free streaming, load sensed processed time, fast cooling, Air Ballasting, Load and performance qualification testing.

For porous loads and glassware equipment– Pre-cycle vacuum, pulsed steaming, post cycle vacuum drying, air intake filters, load and performance qualification testing.

Plastic and other laboratory waste – pre-cycle vacuum, pulsed steaming, free streaming, post-cycle vacuum, exhaust filtration, load sensed process timing, discarded containers, deodorants, room air extraction, load and performance qualification testing.

Need For Free Streaming

An effective autoclave must consist of dry saturated steam. To get this steam, air must be taken out from the load and the chamber in many ways. The entire procedure air removal can be further advanced by ‘free steaming’ where the vent is kept open for the duration of time once the autoclave is above 100 degree Celsius. The turbulent steam further passes through the vent letting the trapped air exit the autoclave.

Importance of Vacuum Systems

In order to maintain an autoclave, effective sterilization is needed to kill micro-organisms by using the combination of saturated steam and load surface. Using a vacuum system, the autoclave will forcibly discard the residual air from the chamber and load through multiple programmed phases with interspersed heating. This effective process allows free circulation of steam, ensuring deep penetration inside the load for effective sterilization.

Effective Ways to Dry Loads

Vacuum alone cannot accomplish the task of sterilizing loads like pipette tips, tubing, porous and instrument loads by completely drying them. The only best choice to dry these loads is by adding a steam jacket to the chamber. The steam jacket along with the vacuum removes all the residual moisture from the load, whilst reducing the cycle times.

Need for Steam/Water Jackets

If laboratories are very often sterilizing loads which need full drying or if looking to maximize throughput by pre-heating the chamber and rapidly cooling it with water, such cases steam/water jackets are required.

Customizing Power Supply as Per Your Need

Generally, large autoclaves and steam generators require 415V three phase supply and for a smaller autoclave, a 230V single phase supply is ideal. Any specific requirements in terms of the power supply can be checked with the manufactures that can accommodate as per your need.

Water Quality in Check

In cases where hard water is used in electrically heated autoclaves or steam generators, it’s advisable to install a water softener. Usually, the calcium built in the water pipes restricts the flow of water, reducing the performance of the autoclave eventually. Hence the water quality needs to be in check when operating autoclaves. RO water is ideally a safe choice to use in autoclaves.

An Effective Drain System

Autoclaves used to discard residual waste in laboratories must be provided with a good quality drainage connection in cases where autoclaves are fitted with free steaming or vacuum options. The purpose of the drainage system is to prevent dispersion and steam and splashes into the working area. An ideal drain system should be capable of holding 134 degree Celsius with a heat resistant pipework, applicable to a joint seal.

Built-in Compressed Air

Most autoclaves have a built-in air compressor. This is mainly required for door seals and control valves on few autoclaves and used for air ballasting systems.

Prevention of Autoclaves

Laboratories where autoclaves are frequently operational need to be well maintained to keep bacteria at bay, which can be harmful to the environment as well as the people working in such labs. If a lab is encountered with bacteria, they stick on to the surfaces for a prolonged period multiplying the bacteria every twenty minutes spreading it at a faster pace. Hence is a multi-user lab there is always a risk of cross-contamination on the lab surfaces including the autoclave cabinet. These bacteria can also be transferred to humans when worked upon it by touching the infected surfaces.

Autoclaves manufactures must take the hygiene issues under consideration, by creating coated frames and panels during production by placing an antibacterial coating. This coating will ensure the protection of the product for lifetime by maintaining clean surfaces, good hygiene and eliminating the threat of cross-contamination.

To Buy Portable Top & Front load Autoclaves from Media visit https://www.firstsourcels.com/medica

Regular Audit to Maintain Sterilization

A good sterility check should be consistently carried out using biological indicators. Data download is perfect for saving records and used for data exchange with the autoclave service company. A well-known Bowie and Dick test are also helpful for proving sterilization.

Placing an Autoclave as Per The Fitment

Autoclaves come in various sizes. Standard dimensions for a floor standing autoclave is 1m to the sides, 2m at the front or twice the length of a loading trolley and 300mm at the rear.

Conclusion

The manufacturers or the sellers of autoclaves are readily available to carry out a survey of the site where the autoclave needs to be placed to understand the dimensions. This could save a lot of time and money in the purchasing process.

FirstSource Laboratory Solutions provides wide range of Sterilizing equipment like: Autoclave, Incubators, Chambers, Ovens, Cabinets of National & International brands at one place. You can compare products Features, Functions & Cost then take your decision to buy. We have one of the best user-friendly E-Commerce portal for Scientific Instruments where you can Browse, Search & Buy product as per your requirement.

FirstSource Laboratory Solutions Official Blog First Indian Scientific Online Shop

FirstSource Laboratory Solutions Official Blog First Indian Scientific Online Shop